- ../

- Assistance /

- Machine servicing

Machine servicing

Prevention

Customer support agreements

We offer complete and customized solutions based on your needs, designed to maximize the life of your machines, both Cat and other brands, maintaining full efficiency over time. We can advise each customer on the best solution to adopt, from the most simple to the most complete, e.g. condition monitoring service with remote control, fluid analysis and ordinary and extraordinary maintenance.

During routine maintenance the following are performed:

- Controls and registrations

- Instrumental tests

- Security checks and controls

- Oil and filter replacement

- Carrying out of small repairs free of charge

as stated in the manufacturer's user and maintenance manual. You are guaranteed:

- The use of an increasingly efficient machine

- Reduced consumption

- Minimized and scheduled downtime

- Preserved value of the machine

Condition monitoring

Based on the data transmitted via Vision Link satellite technology our prevention team analyzes the main operating parameters of your machines, comparing them with those provided by Cat and with historical data. Should any anomaly emerge the team reports the possible risks and recommends what action should be taken.

By accessing the Vision Link website through our portal you can constantly keep track of consumption data, location and any machine malfunction codes transmitted by the Product Link device installed on your machines.

You can:

Receive an accurate report on situations of potential risk or incorrect use and relative suggestions

- Check and reduce consumption for the entire fleet

- Improve machine performance and avoid unexpected costs

- Carry out maintenance punctually, reducing operating costs

- Customers who activate the service on 3 or more machines receive a monthly fleet usage report including a comparison with machines of the same range in Italy

Fluid Analysis

Our specialists carry out more than 40,000 analyses per year on samples taken from the machines of our customers, in order to monitor wear and tear of the main mechanical components and detect the existence of pollutants (not only water, diesel fuel or ashes but up to 18 different elements and with sizes of up to 5 microns) in fluids. A specialized staff compares the level of the various pollutants detected with the reference values provided by the manufacturer and with the previous analyses, and sends back an accurate diagnosis to help prevent breakage and plan maintenance interventions, thus optimizing downtime.

Our customers receive the results of the analysis in electronic format, and they are also available online via the Vision Link portal (if the machines are covered by this service).

Advantages:

Monitoring the wear and tear of the main mechanical components and scheduling any necessary downtime

- Intervening before a malfunction occurs

Reduced repair times thanks to simplified diagnostics that go straight to the heart of the problem

- Extending the life of lubricants

EMSolutions

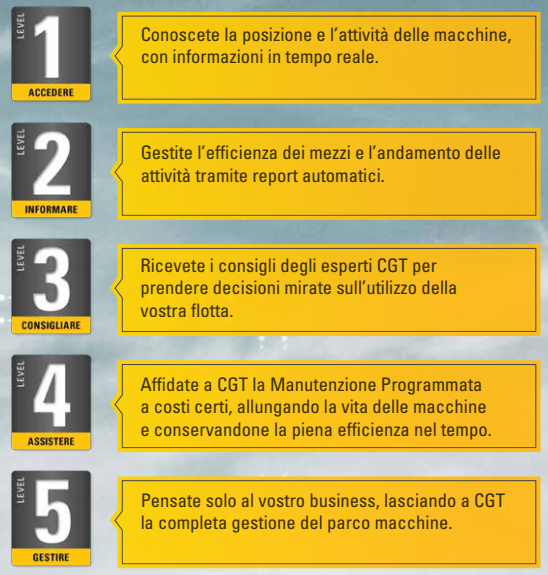

Equipment Management Solutions (EMSolutions) are created to help you manage your activities more efficiently and reduce the operating costs of your Cat machines. Organized into five different levels, these solutions provide you with all the assistance you need, whether you prefer to do your own maintenance or assign it to us so you can focus completely on your work.

Repair before failure options

We offer a wide range of repair before failure solutions for replacing the parts of your machines before they break. Thanks to the expertise we have gained over the years and to the careful monitoring of fluid analysis data and that of Vision Link we can help you choose the best time to carry out planned preventive replacements.

Advantages:

- Constantly top performance, guaranteed by the use of original and efficient parts

- 6-month warranty on all interventions

- Fixed and constantly affordable costs

Assistance

Nationwide presence

We operate in every region of Italy, both through direct branches equipped with workshops and through resident technicians, guaranteeing maximum coverage throughout the country. We have over 350 technicians with workshop vans fitted out with advanced diagnostic equipment. Our technical consultants have a thorough knowledge of both Cat and other brand machines, and are constantly at hand to help customers keep them fully efficient, providing free periodic technical inspections, detailed reports and advice on what measures to take.

Advantages:

- Reduction of unplanned downtime

- Close to your building sites

- Interventions on Saturdays also

- Same day interventions when machine is at a standstill

Parts Repair Centre

We place at the service of our customers a specialized workshop for the repair and overhaul of parts, manned by 20 dedicated technicians and equipped with the latest special equipment. Every year the workshop overhauls over 2,000 parts from every brand and model, including:

- Engines

- Hydraulic pumps and engines

- Cylinders

- Axles and adapters

- Equipment (hydraulic hammers, grapples, shears, etc.)

- Gearboxes

In choosing CGT you have the guarantee of a specialized centre capable of making repairs that would otherwise be impossible.

Paving machines

Road paving requires specialized professionals with advanced technical and applicative skills. It is also an activity that is often carried out on weekends, holidays and sometimes at night.

To meet these special needs we have put together a dedicated team of highly-qualified technicians, application consultants and paving product specialists who are able to work with the utmost professional competence on these machines. One single contact number - 02.92.364.190 – is at our customers’ disposal for every type of request.

Advantages

Immediate emergency consulting from an experienced professional who provides an initial diagnosis by telephone

A team of professional and dedicated technicians with extensive training and experience in the repair and maintenance of road construction machines

Support from a technical applications consultant and a technical product consultant who can give you useful tips for working with maximum efficiency

On call 24 hours a day, 7 days a week

Sandvik and Komptech

We are dealers for Italy of Sandvik mobile crushers and screeners, and of Komptech grinders, chippers and all other models of the range. For these products, which require specific expertise in the event of requests for assistance, we have created a dedicated team of highly-qualified consultants and technicians with specially equipped workshop vans, who are able to quickly satisfy any specific request.

This dedicated support team is capable of operating on any brand product and can be reached through a single number: 02.92.364.188. Please feel free to contact us and submit your request.

Advantages

- Immediate emergency consulting from an expert who will provide an initial diagnosis by telephone

Co-ordination of dedicated technicians specializing in crushing and screening, with extensive training and experience in the repair and maintenance of these machines

- Support from a technical applications consultant and a technical product consultant who can give you useful tips for working with maximum efficiency

Assistance for every brand and model

Acting as a one-stop source to cater to all your needs, we guarantee the safety and reliability that is essential to your business. High quality CGT technical assistance is provided not only for Caterpillar machines but also for other brands in the earth-moving and lifting sectors, as well as engines.

Advantages

- - A professional one-stop source providing assistance for your entire fleet

- - A precise nationwide point of reference

- - Time and money saving

Training Centre

Centro Scuola

Dedicated to training our technicians, the CGT Training Centre is a facility designed to guarantee continuous updating and high professional standards. The experience of our teachers and a modern teaching approach, as well as a consolidated organization, make our facility one of the centres of excellence recognized by Caterpillar for technical training.

The Training Centre is also accredited by Regione Lombardia for the provision of educational services and vocational training in accordance with DGR no. 2412 of 26/10/2011 and is therefore qualified to offer courses to the staff of CGT customers.

Courses designed for external staff include those geared to qualifying operators, as required under State/Regional Councils Agreement no. 53/CSR of February 22, 2012, in the use of:

- Earth moving machines (hydraulic excavators, front-end and backhoe loaders)

- Self-propelled stackers with on-board driver

- Mobile elevating work platforms (MEWP)

- Truck mounted cranes

The courses consist of theory lessons in the classroom, practical exercises and a final examination which, if passed, entitles the operator to a certificate attesting to the relevant qualification. The courses may also be held at one of the CGT branches or, on request and for groups of at least 6 operators, on the customers’ premises or construction site.Vantaggi:

- Reliability of the professional expertise and continuous updating of CGT technicians

Correct use of the machines by the operators, which means greater productivity, safety and efficiency

- High level of professionalism of the teachers of CGT, leader in Italy since 1934